Development of the Rigby System

Testing and Development

With more than 600 projects and decades of experience as a wastewater expert, David Rigby knew technology could radically transform how water is treated in commercial and municipal environments throughout the world.

After Dr. Rigby designed the reactor, initial sampling and testing was performed in Virginia at Arlington County and Prince William County wastewater treatment plants.

Continuous flow tests were run using feed pumps. Each sample procedure lasted approximately 1 hour, so the untreated water quality changed from sample to sample. The initial sampling led to field testing on specific contaminants involving Coca-Cola, Royal Caribbean International, US Bureau of Land Management, Ministry of Defence (UK) and a commercial laundry (UAE). Read more in our case studies.

Summary of conclusions:

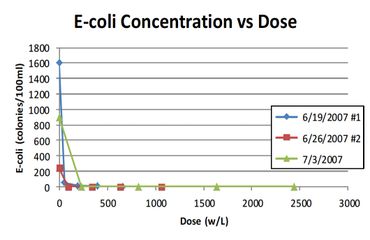

- 90+% reduction of raw wastewater

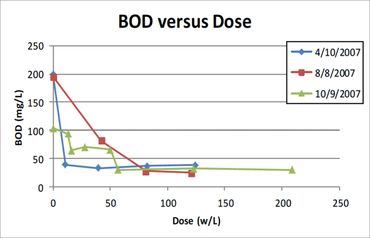

- BOD 100% kill of bacteria in every test on every wastewater

- Significant reduction of raw wastewater

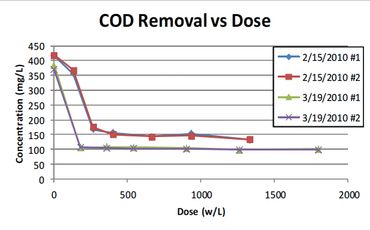

- COD Reduction of TKN in raw wastewater

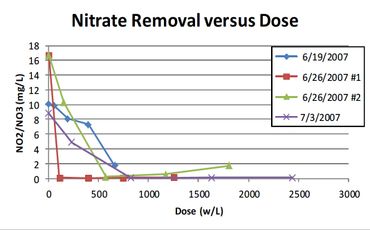

- 90+% reduction of nitrate and phosphorous from secondary effluent

- Effective simultaneous reduction of TSS, oils and metals

- Effectively separated FOG and petroleum oils from wastewater

- Aluminum electrodes performed better than iron electrodes

- HRT between 2 - 5 minutes optimal Power dose between 200 – 500 w/L optimal

Cost effective, simple to operate and proven results

Test Results

the rigby system

Copyright © 2020 Electro-Chemistry - All Rights Reserved